Principle of filtration

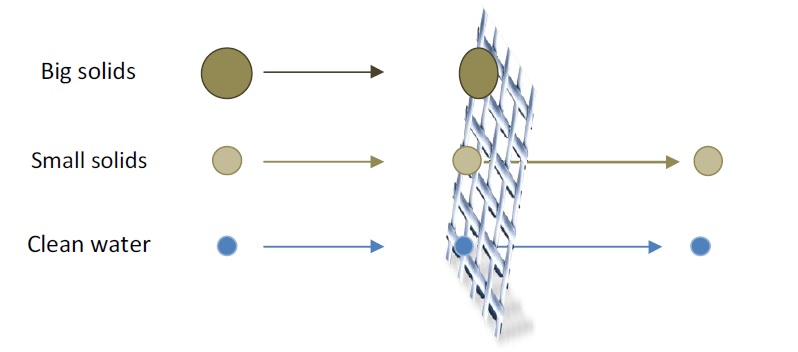

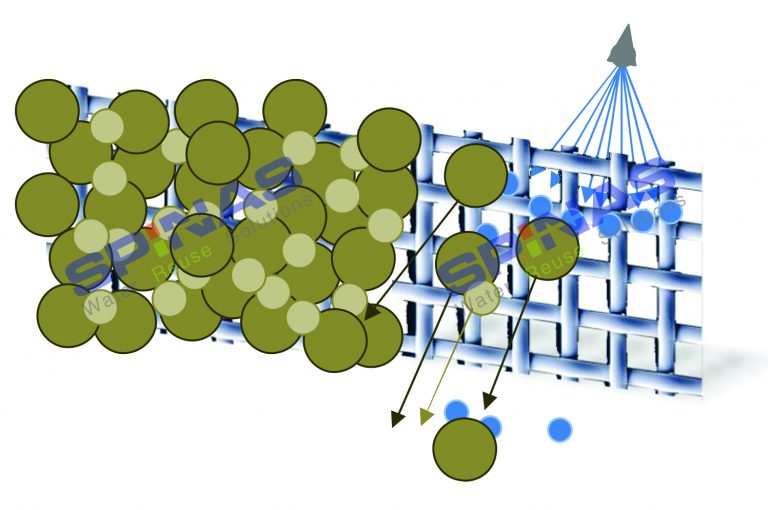

Water containing solid particles flows through the filter cloth/sieve of the given structure which has openings of a certain size. The filter cloth traps impurities which are bigger than openings in the filter cloth while smaller particles, including water, flow through the filter out. As the filter cloth slowly becomes clogged by the increasing amount of filtered impurities, the filter cloth must be backwashed so it can work again.

SS (mg/l), mesh (micrones)

Suspended solids (SS) are in mg/l and show how many SS (e.g. flocs and other debris) are in one liter of water. It is just a reference parameter. It is also important to know what solids look like and select the mesh accordingly.

Secondary filter layer

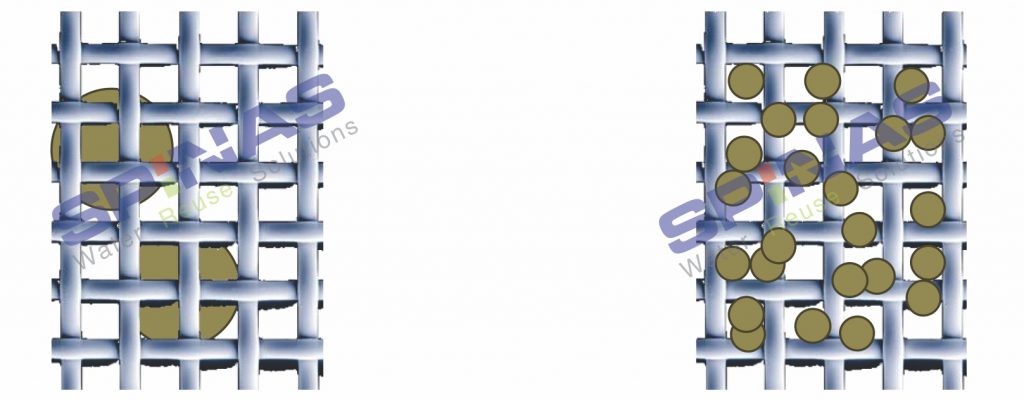

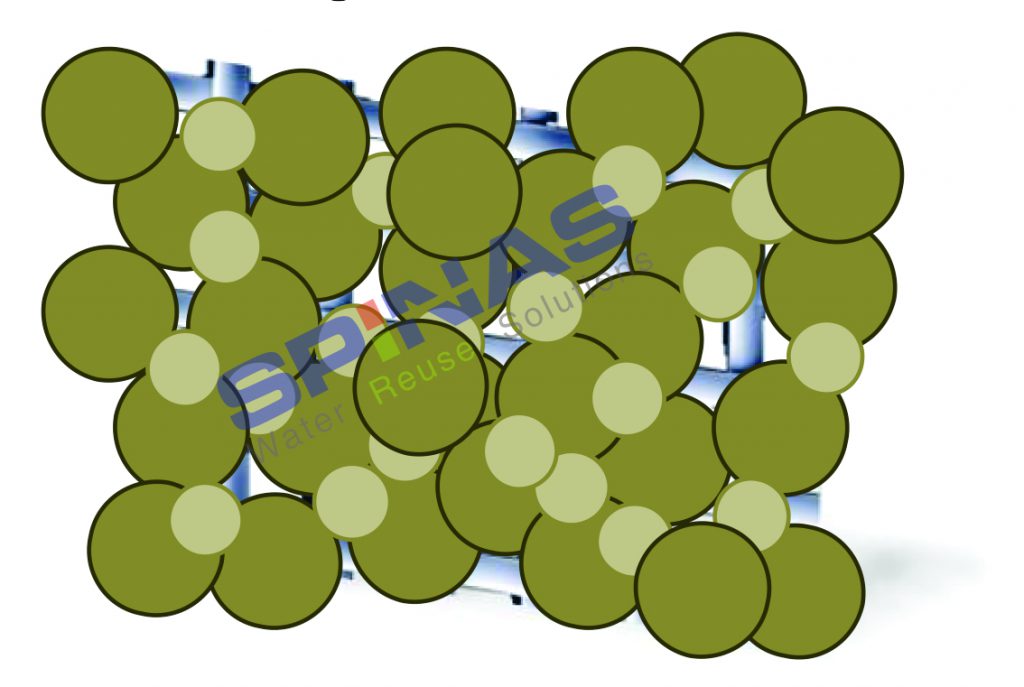

Filter capacity is greatly influenced not only by the volume but also by the nature of filtered SS. What matters is their size (flat particles tend to clog openings more easily than round ones), mechanical strength (compact particle can be filtered better than non-compact slimy ones) and the proportion of small and big particles in the total volume of influent. If a certain number of compact solids, bigger than the mesh openings, occur, it can result in a thin layer of sludge – secondary filter layer, which is capable of catching solids which are considerably smaller than the size of mesh openings. It is therefore advisable to choose a filter with a greater filter area so the filter idle time is as long as possible and an efficient secondary filter layer can form on the inner side of the mesh. This layer is flushed down to the sludge channel during backwash.

SPINAS works with the approach of delivering services and effective and efficient solutions in supplying and equipping waste water treatment and recycling technologies.

In 1392, the company started its business in commerce. Since 2014, the focus has been on special technologies … Read More